High Speed Auto Walk Planetary System Floor Polisher For Concrete

Quick Detail:

| Name | 12 heads floor polishing machine | Application | Marble, granite, terrazzo, concrete floor | | Type | S-X12-750 | Function | Leveling, polishing, grinding, renovating |

Description: - 750 mm large work areas improve the work efficiency.

- Separated body make it easy for carrying.

- With multifunction plate include magnetic discs and Velcro discs meet different clients’ demand.

- Four plates, each fix 3 pieces small discs, total 12 pieces small discs one machine, each time need fix 12 pieces polishing pads.

- Handle is adjustable, is easy to control.

- With inverter could adjust the speed from 0 to 1500 rmp.

- Use good quality bearing.

Specification:

| Type | S-X12-750 | | Power | 11KW | | Voltage | 380V-440V | | Inverter | 15KW | | Speed | 0-1500 rpm | | Grinding discs | 12pcs | | Work width | 750mm | | Weight | 490kg | | Water tank | 30L |

Detail picture:

Planetary Grinder Operation instruction: - Fix the grinding disc, please put the handle in horizontal position, press the handle down by power to make the bottom disc tilting, and the grinding disc turn up, and stick the grinding pads on.

- Lay the machine back to the floor slowly to let the grinding pads reach the floor. (Please lay lightly).

- Put the add weight down to the back of the machine, wear the dustband.

- Fix the power supply wire. (Safety operation)

- Hold the machine handle, pull out the bolt, then pull and push the handle adjuster bar to adjust the handle in a proper position for operation, fix the handle by the bolt at last.

- Turn on the water switch when need water, if you would like dry grinding, please connect the outside dust collect with dust vacuum cleaner.

- Turn on the power supply switch and the machine begin to work.

- Stop the machine to change the grinding pads.

- Keep the speed above 1000rpm during operation.

Operation Safety: - While operation, to keep safe must wear safety helmet and safety shoes, in addition, use mask and earplug according to the operation condition.

- Non-against exploding construction, so absolutely do not put flammable substances of petrol, thinner and gas etc nearby.

- Regarding to the noise, please comply with relative rules in local,do not give trouble to the surroundings.

- Absolutely do not touch the motor during operation, otherwise it's easy to scald; also parts of the grinding heads will be too hot to touch.

- It had better use our grinding assessories or the appointed products made by our company such as grinding pads , if use other products, it perhaps will injure operator's body. Therefore the incident does not belong to the scope of product quality if it happens during use other company's accessories .

- If machine runs abnormally , and un-usual condition during using the machine, immediately stop the operation, examine and repair it after confirming the safety.

Forbidden operation condition:

Available abrasive: - Diamond resin pads

- Diamond grinding shoes

- Metal diamond grinding discs

S-X12 Planetary Grinding Machine

Specification:

|

Model

|

S-X12-800

|

S-X12-600

|

|

Voltage (V)

|

380V

|

380V

|

|

Power (HP)

|

15PH

/ 11KW

|

11HP/7.5KW

|

|

Inverter (HP)

|

20HP/15KW

|

7.5HP/11KW

|

|

Autorotation rate (RPM)

|

0-1250

|

0-1250

|

|

Revolution speed (RPM)

|

0-320

|

0-320

|

|

Work width(mm2)

|

800*800

|

600*600

|

|

Pads qty (PC)

|

12

|

12

|

|

Water tank (L)

|

30L

|

30L

|

|

NW (KG)

|

450kg

|

350kg

|

|

Effect

|

Same as 4pcs of 12 heads machine

|

Feature:

1.Planetary system, work efficiency is about 4 pieces of the 12 heads grinding machine, it saves cost of labor.

2.Machine handle could rotary movement by 360 degree.

3.800mm width work area improve the work efficiency to save time and human cost.

4.Use multifunction plate which with magnetic.

5.Two layer gear, total 15pcs gear.

Application:

For stone leveling, stone polishing and grinding, concrete polishing and grinding, also apply to remove the old coat of epoxy etc...

Detailed Images:

Accessories:

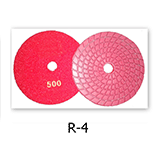

Wet polishing pads (For marble, granite and concrete):

Wet polishing pads (For concrete):

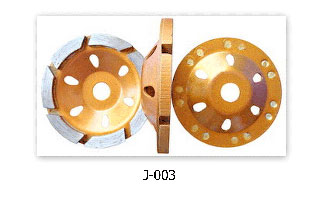

Diamond grinding wheel:

Packing:

|